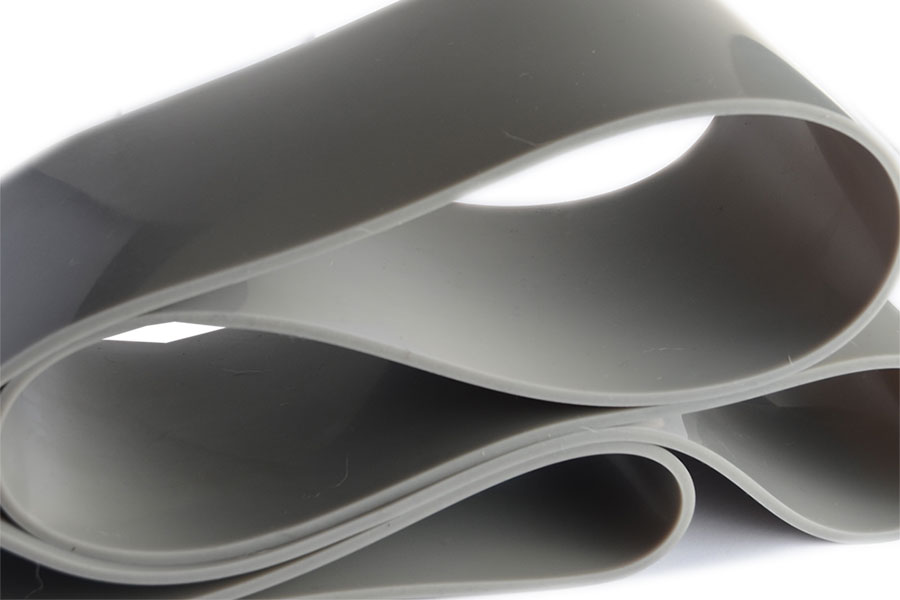

Discover the pinnacle of vacuum pressing technology with our SM-55 Grey – a premium-grade, grey-colored silicone rubber membrane engineered with high-performance components for unmatched durability and flexibility. Designed in the heart of the European Union, the SM-55 Grey stands as a testament to superior craftsmanship and material innovation.

The Grey silicone sheet is meticulously crafted to meet the rigorous demands of membrane presses, accommodating both positive and negative pressure environments with ease. Its robust composition ensures an exceptional resistance to tearing, alongside an impressive capacity to withstand dynamic tension and compression loads, making it a reliable choice for high-stakes applications.

With an outstanding temperature resistance of up to 200°C, this membrane is ideally suited for challenging environments, particularly within the woodworking industry. Its ability to perform under high heat conditions makes it perfect for the precise covering of PVC foil, veneer, paper, and leather, ensuring a flawless finish and enhanced product durability.

Boasting an elongation capability of up to 650%, the membrane offers extraordinary flexibility, allowing it to conform seamlessly to intricate shapes and complex designs. This remarkable feature is crucial for the effective shaping of composite materials, ensuring even pressure distribution and a consistent application across diverse surfaces.

Beyond its primary function in membrane presses, the SM-55 Grey excels in a variety of applications:

- Laminating: Achieve superior adhesion and a smooth finish when laminating foil, veneer, paper, and leather, enhancing the aesthetic and functional quality of your products.

- Composite Material Shaping: The SM-55 Grey's adaptability makes it an ideal choice for molding and shaping composite materials, offering precision and reliability in every use.

Smooth Finish for Optimal Performance. The membrane is supplied with a smooth finish, ensuring not only a sleek appearance but also facilitating ease of use. This smooth surface significantly reduces the risk of adhesion to workpieces, streamlines the cleaning process, and contributes to the overall efficiency and longevity of the membrane.

Proudly manufactured in the European Union, the SM-55 Grey embodies the highest standards of quality and environmental responsibility. When you choose the top grade membrane, you're not just selecting a product; you're investing in a solution that brings European craftsmanship and innovation to your doorstep.

Explore the transformative potential of the Silicone Membrane SM-55 Grey for your pressing, laminating, and material shaping needs. Embrace the future of manufacturing with a membrane that offers durability, flexibility, and performance, all wrapped up in the sophisticated hue of grey.

Get a price

Download

Physical Properties

|

Type:

|

SM-55-Grey | |||

|---|---|---|---|---|

|

Compound:

|

A-SU 55-82 | |||

|

Model:

|

SM-55-2-1660 | SM-55-3-1660 | ||

|

Thickness, mm:

|

2 | 3 | ||

|

Width, mm:

|

1660 | 1660 |

Model:

|

SM-55-2-3000 | SM-55-3-3000 |

|

Thickness, mm:

|

2 | 3 | ||

|

Width, mm:

|

3000 | 3000 | ||

|

Length, m:

|

10 | 10 | ||

|

Working temperature, max C:

|

+200 | |||

|

Hardness, Shore A:

|

55 +/-5 | |||

|

Elasticity, %:

|

650 | |||

|

Density, g/cm3:

|

1,16 +/- 0,02 | |||

|

Tensile strength, N/mm2, (Mpa):

|

8.5 | |||

|

Tear strength, N/mm:

|

35 | |||

|

Color:

|

Grey

|

|||

|

Surface:

|

Smooth

|

|||