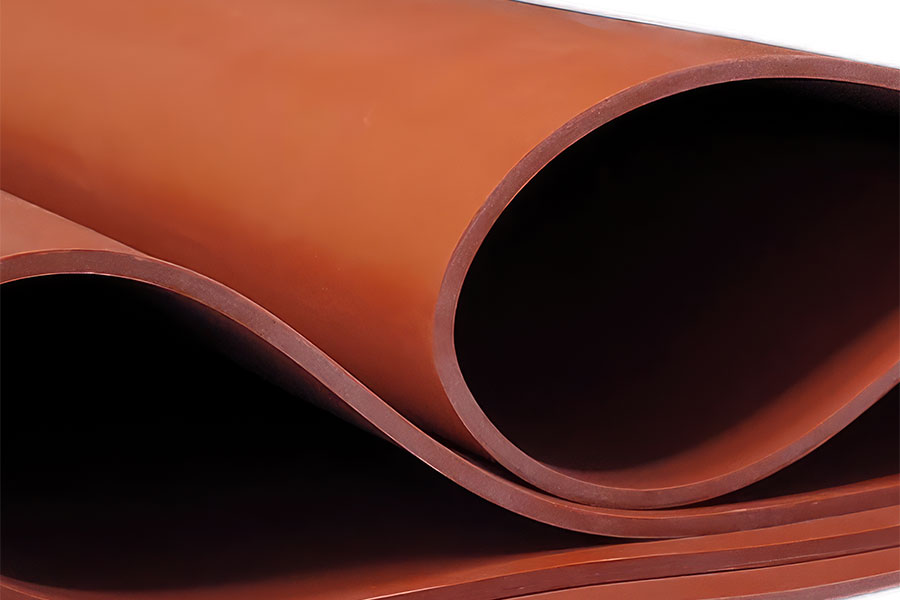

The Silicone Membrane SM 40 Brown represents a significant advancement in the field of industrial materials, combining the hardness and flexibility required for the most demanding applications. This high-quality red-brown silicone rubber membrane, manufactured within the stringent quality controls of the European Union, is engineered to meet the diverse needs of modern manufacturing processes.

One of the standout features of the SM 40 Brown is its exceptional tolerance to high temperatures, capable of withstanding environments up to 250°C. This remarkable characteristic makes it particularly suitable for use in sublimation machines, where high heat is a fundamental aspect of the process. The ability to operate effectively at such temperatures opens up a wide range of applications, ensuring that the SM 40 Brown can meet the needs of industries where heat resistance is critical.

With an elongation potential of up to 700%, the SM 40 Brown sets a new standard for flexibility in silicone membranes. This level of elasticity allows the membrane to stretch significantly without losing its integrity, making it an ideal choice for complex molds and shapes. The optimal combination of strength and elasticity ensures that the membrane can endure the rigors of continuous use while maintaining its shape and effectiveness.

The SM 40 Brown is not just limited to sublimation processes. Its unique properties make it an excellent choice for a variety of applications, including vacuum and thermoforming presses. It is particularly effective in the laminating of foil and veneer, contributing to the production of high-quality finishes in the woodworking and furniture industries.

Furthermore, the SM 40 Brown plays a crucial role in the production of triplex and the shaping of solid surfaces and thermoplastic materials. Its ability to evenly distribute heat and pressure ensures a consistent and flawless finish, crucial for the production of high-end products.

The smooth finish of the SM 40 Brown is more than just an aesthetic feature; it significantly enhances the membrane's performance. This finish facilitates easier removal from the workpieces, reducing the risk of damage and ensuring a cleaner process. Additionally, the smooth surface makes cleaning and maintenance of the membrane more straightforward, contributing to a longer lifespan and consistent performance.

The introduction of the Silicone Membrane SM 40 Brown into the market marks a significant milestone for industries in search of advanced material solutions. Its combination of high-temperature resistance, exceptional elasticity, and versatile application potential makes it a valuable asset for businesses aiming to enhance their production capabilities and product quality.

Choosing the SM 40 Brown means investing in a solution that brings together the latest in material science and manufacturing technology, ensuring that your operations are not just efficient but also poised for future advancements. Whether for sublimation, laminating, or thermoforming processes, the SM 40 Brown is designed to exceed expectations and drive innovation in manufacturing.

Get a price

Download

Physical Properties

|

Type:

|

SM-40-Brown | |||

|---|---|---|---|---|

|

Model:

|

SM-40-B-1-1600 | SM-40-B-2-1600 | SM-40-B-3-1600 | |

|

Compound:

|

A-SU 40-79 | |||

|

Thickness, mm:

|

1 | 2 | 3 | |

|

Width, mm:

|

1600 | |||

|

Length, m:

|

20 | 12 | ||

|

Working temperature, max C:

|

+250 | |||

|

Hardness, Shore A:

|

42 +/-5 | |||

|

Elasticity, %:

|

700 | |||

|

Density, g/cm3:

|

1,13 +/- 0,02 | |||

|

Tensile strength, N/mm2, (Mpa):

|

8 | |||

|

Tear strength, N/mm:

|

25 | |||

|

Color:

|

Brown

|

|||

|

Surface:

|

Smooth

|

|||